Retrofitting buses - An easy step for urban areas to reach zero-emission mobility

Buses and coaches, which are generally diesel-powered, make a significant contribution not only to greenhouse gas (GHG) emissions, but also to air pollution (micro-particles) in urban areas. Decarbonizing public transport is now a priority for local authorities. Fleet managers are therefore called upon to modernize their vehicles. Among the various solutions available, retrofitting is a promising strategy for moving towards zero-emission mobility.

1 - The challenges of decarbonizing public transport:

1.1 Reducing CO2 emissions

The transportation is the main source of greenhouse gas (GHG) emissions, and urban areas are particularly affected. Reducing these emissions is therefore essential not only to comply with international climate agreements, but also to improve urban air quality, which is directly linked to public health. Given their major role in public transport, buses and coaches are among the first vehicles concerned.

1.2 Regulatory objectives and expectations for urban air quality

Many cities around the world must now comply with strict environmental standards, often reinforced by regulations such as Low Emission Zones (LEZ). These requirements, coupled with growing public awareness, are driving fleet managers to adopt low-emission solutions. Compliance with these standards therefore goes beyond regulatory compliance and becomes a criterion of choice for users who favor greener modes of transport.

2 - Retrofitting: a promising solution

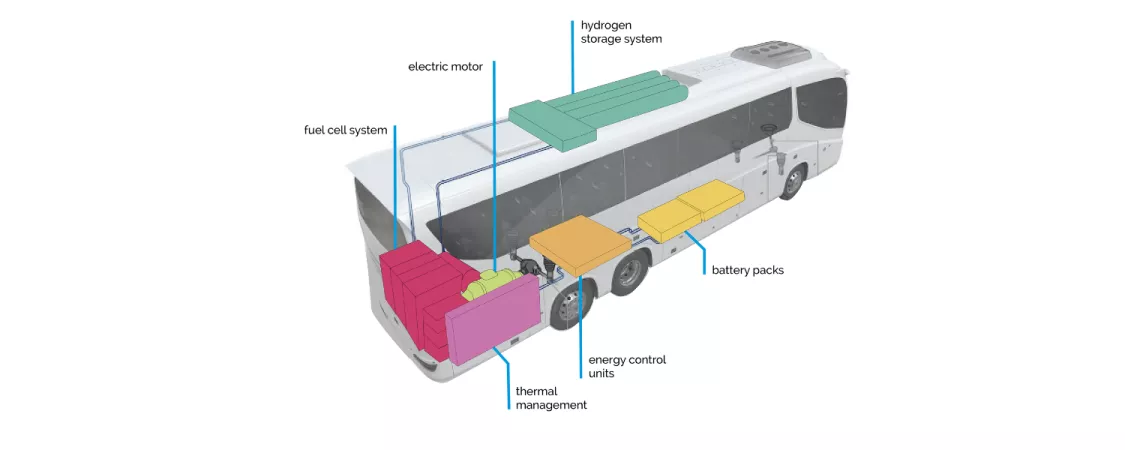

Among the solutions for achieving zero-emission mobility, retrofitting offers many advantages. It involves replacing the internal combustion engine of a bus or coach with an all-electric drivelineunit, powered either by a battery or a hydrogen fuel cell..

Read more: How Hydrogen Fuel Cells Work in Buses: A Simple Explanation

A third solution consists of changing the diesel engine, and adding a hydrogen storage and distribution system for direct use. However, this last option does not reduce greenhouse gas emissions as significantly as the first two. In fact, the internal combustion engine will continue to emit nitrogen oxide, unlike the fuel cell system.

2.1 An economic advantage

Retrofitting existing buses or coaches is often more economical than purchasing new vehicles. By using existing frameworks and structures, fleet managers can save the substantial costs linked to the purchase of new buses. Besides, in countries such as France, Germany, Netherlands and for many on-road applications, operators and integrators can benefit from local subsidies.

2.2 Extending bus life and reducing waste

By opting for retrofitting, fleet managers can extend the life of existing buses. This option minimizes the environmental impact associated with the manufacturing of new buses and the disposal of old ones.

2.3 Flexibility for different fleet configurations

Retrofitting offers great flexibility and can be adapted to various types and sizes of bus or coach. This flexibility enables fleet managers to selectively update their vehicles according to their specific needs and operational requirements. This ensures gradual modernization, without disrupting overall service efficiency.

3 - The advantages of hydrogen technology

3.1 Higher energy performance and greater range

Hydrogen fuel cell technology is primarily known for its high energy performance and greater range than an electric battery. (Click here to know more).

"We're opting for hydrogen technology, which is much more relevant

for heavy-duty mobility“

Vincent Lemaire, CEO, Safra

3.2 Faster refueling time

Fuel Cell Electric Buses offer greater range and faster refueling than electric battery-based solutions. Whereas battery electric buses can take several hours to fully recharge, hydrogen-powered buses can be refueled in just a few minutes. This increased efficiency means that hydrogen vehicles can remain in service for longer, without the frequent interruptions required to recharge the batteries, which is essential for maintaining a fluid and continuous public transport offer . Furthermore, only one refueling point is needed for the entire fleet to maintain uptime, while for batteries powered vehicles the operator needs to have either many charging points at the depot or more buses in order to keep the pace of operations.

3.3 Lower operating costs

Although battery powered electric buses generally have lower maintenance costs than diesel engines, hydrogen fuel cells offer even greater durability with reduced maintenance requirements compared to battery management, which can require costly replacements and specific life-cycle management. In addition, the energy efficiency of hydrogen fuel cells can lead to long-term savings, especially in a context of high electricity prices.

Read more: The cost efficiency of hydrogen buses: A long-term perspective

3.4 Image benefits

Opting for hydrogen retrofit can also reinforce fleet managers' image as leaders in innovation and sustainability. This technological advance not only demonstrates a commitment to high ecological standards, but also ensures compliance with strict future environmental regulations.

4 - How is a hydrogen retrofit carried out?

4.1 Fleet assessment and selection of buses suitable for retrofit

The retrofit process starts with a careful assessment of the existing fleet to identify the best candidates for retrofit. This selection is based on the age and model of the vehicle, general condition and structural compatibility with fuel cell systems. Detailed analyses also include a cost-benefit assessment for each bus, ensuring that the retrofit investment delivers tangible added value.

4.2 Partnerships with technology suppliers and installation steps

Once the buses have been selected, fleet managers need to forge partnerships with the companies specialized in retrofit and in hydrogen fuel cell technology . These partners will not only supply the necessary components, but will also oversee the design and implementation of the systems. The actual installation must be carried out by qualified technicians who will ensure that all systems operate correctly and safely, in compliance with industry and regulatory standards. Depending on the country the retrofitted buses must also go through a local authority homologation process

4.3 Staff training and operational integration

Once the buses or coaches have been converted, staff training is essential to ensure a smooth transition to daily use of hydrogen-powered buses. Drivers must be trained to get the best out of the vehicle at use and optimize performance. This training must cover the technical aspects of bus operation, and maintenance protocols. In parallel, a phase of testing and operational integration is required to ensure that retrofitted buses are effectively integrated into active service, with ongoing monitoring to optimize their performance and reliability.

5. Conclusion

Bus and coach retrofitting is a strategic and front runner solution for fleet managers who aspire to transform their operations into models of sustainability and efficiency rapidly. This approach promotes the extension of the useful life of existing vehicles and a transition to zero-emission mobility without the investment involved in complete fleet replacement.

Thanks to its advantages in terms of range, rapid refueling time and reduced maintenance, hydrogen retrofitting outperforms the electric battery option, offering a suitable response to the high demands of public transport. As urban areas tighten environmental regulations and hydrogen technology evolves, retrofitting existing buses and coaches with this carbon-free technology is emerging as a must-have option for fleet managers.

Download our Ebook: Buses & LCVs: 5 key considerations for product selection and technical specifications