Why are fuel cells better suited than batteries for material handling applications?

Benefit 1: Total Cost of Ownership.

The Total Cost of Ownership (TCO) is the complete financial estimate of acquiring, operating, maintaining, and disposing of an asset over its lifecycle, including initial purchase price, operating costs, maintenance, depreciation, downtime, and disposal costs.

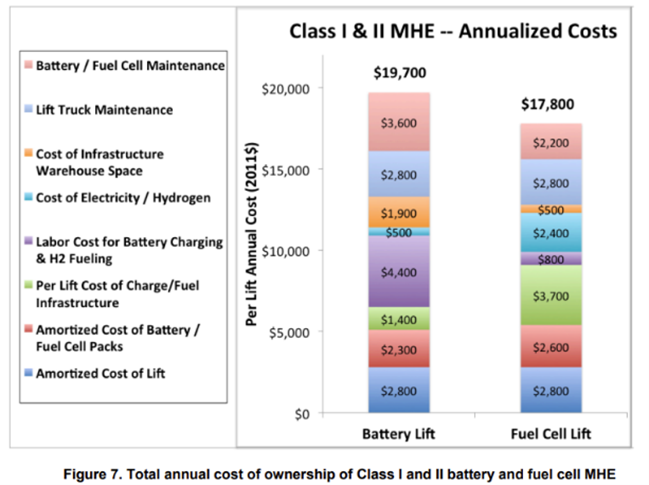

It provides a comprehensive view to make informed decisions about investments and purchases. The TCO for a class 1 & 2 lift truck is 10% lower when powered by a fuel cell compared to battery technology. Similarly, for a class 3 lift truck, the TCO is 5% lower with fuel cell technology.

These savings are expected to increase as technology advances1. According to the US Department of Energy (DoE) objectives, the cost of the kg of H2 will tend to decrease by 80% to 1$ per 1 kilogram at the end of the decades.

Benefit 2: A faster refueling for a better productivity & saving time.

Refueling a fuel cell vehicle with hydrogen is 80% faster than recharging a battery-powered vehicle2. This speed is vital in industries where downtime directly impacts productivity and efficiency. Material handling trucks powered by fuel cells can maximize operational time and minimize idle time, effectively reducing overall downtime. While traditional battery-powered forklifts need between 3-5 hours to recharge, fuel cell forklifts require just 2-3 minutes.

All these elements reduce the unproductive labor cost of a company.

As the recharge time is similar to diesel or CNG, this allows the purchase of a single forklift rather than several forklifts or BBR to compensate the recharging time of a battery forklift. Fuel cell forklifts enable uninterrupted operation across all three shifts of a day, without incurring unnecessary labor costs due to downtime.

Benefit 3: Warehouse space efficiency.

Hydrogen refueling stations require 75% less space compared to battery recharging stations2. In the logistics sector, available space directly correlates with return on investment. Therefore, adopting fuel cell technology presents a superior approach to maximizing space utilization in your warehouse.

The indoor warehouse space allocated for electric recharging stations is approximately 230 m2, whereas for a hydrogen refueling station, it's around 45 m2, which is over five times less.

More space = More productivity

Benefit 4: ZERO CO2 emission at use, ZERO pollutants, ZERO noise.

The adoption of fuel cell technology unlocks three crucial benefits, what we call the "3 ZEROs":

ZERO CO2 emission at use

Unlike internal combustion engines, our fuel cells produce only water so no CO2 emissions during use, contributing to a cleaner environment and aligning with sustainability goals.

ZERO pollutants at use

With our fuel cell technology, you can say goodbye to pollutants typically associated with internal combustion engines. This means no harmful pollutants such as carbon monoxide, particulate matter, and nitrogen oxides, in your warehouse, creating a healthier and safer work environment for your employees.

ZERO noise

Embracing our fuel cell solution means embracing a quieter workplace. Unlike noisy diesel or gas-powered forklifts, our technology operates silently, significantly reducing noise pollution in your facility. This not only enhances the comfort of your workforce but also minimizes disturbances in surrounding areas.

Benefit 5: Maintenance & recycling.

Benefit 5: Maintenance & recycling.

Fuel cell systems require less maintenance because they don’t need the watering, equalizing, charging, or cleaning that is required with lead-acid batteries. Additionally, the recycling of fuel cell is easy due to existing recycling platinum technology getting back the fuel cell value and limiting impact on the planet whereas Lithium recycling is not mature yet.

Benefit 6: Consistent Performance.

The operational speed of fuel cell forklifts remains nearly constant regardless of the fuel level, ranging from 0% to 100% in the tank. In contrast, lead-acid batteries can experience power loss of up to 14% in a single pass under normal temperatures, which can escalate to 25% to 50% in cold or freezer storage facilities3.

Benefit 7: No dependance on the temperature.

Fuel cell forklifts maintain consistent power and efficiency even in extreme temperatures. In contrast, lead-acid battery-powered forklifts can lose up to 50% of their operating speed in cold environments, reducing their operational time to around four hours. Li-ion batteries may lose up to 20% of their performance in extreme cold.

For cold storage professionals, this disparity is significant: hydrogen fuel cells remain unaffected by cold conditions and can operate for twice as long per fill compared to battery-powered units. This enables operators to maintain productivity for longer periods in cold storage environments.

Benefit 8: COMPACTNESS and INTEGRATION.

Benefit 8: COMPACTNESS and INTEGRATION.

The Symbio fuel cell is a compact solution designed to seamlessly integrate into your current fleet of forklifts and BBRs. Our fuel cell technology covers a wide range of power requirements, spanning from 48 V to 90 V. This means you can optimize your operations without the need for significant equipment modifications and enormous investments, ensuring a smooth transition to cleaner, more efficient power sources for your materials handling needs.

Benefit 9: Towards renewables hydrogen.

The battery stores the energy, the fuel cell transforms the energy. Batteries technologies must be charged on the electric grid which is increasingly vulnerable to frequent natural disasters such as hurricanes, floods, extreme heat, and cold weather.

Moreover, electric grids have experienced significant strain as a result of heightened usage and additional demands. 60% of the electricity produced in the US comes from no renewable energy sources which is a big problem for the sustainability of an economy. Without considering the fluctuation of electricity costs based on demand.

It's advantageous for a company not to rely on the electric grid. Its better to use fuel cell hydrogen forklift with hydrogen produce on site based on renewable electricity.

Conclusion.

Conclusion.

By opting for fuel cell technology for class 1 & 2 material handling equipment, costs can be decreased by nearly 25%, resulting in annual costs of $21,000 per lift truck, compared to $27,300 for battery-powered counterparts. Similarly, for class 3 equipment, the reduction in costs could be around 20%1.

As renewable hydrogen costs are expected to significantly decrease in the coming years, fuel cells are poised to emerge as the future propulsion technology for forklifts.

- National Renewable Energy Laboratory (NREL)

- US Department of Energy (DoE)

- BCC Research

Sources

Lowden, O. (2023, November 15). 7 key advantages of fuel cell forklifts.

DOE. Thomas, S. (2009, March 27). Fuel cell and battery electric vehicles compared.

EIA. (2022). Electricity in the U.S. - U.S. Energy information administration

Toyota Forklifts. (2023, March 28). Hydrogen fuel cell forklifts: an alternative energy solution.

NREL. Ramsden, T. (2013, April). An evaluation of the total cost of ownership of fuel cell powered material handling equipment.

DOE. (2021, June 7). Hydrogen shot.